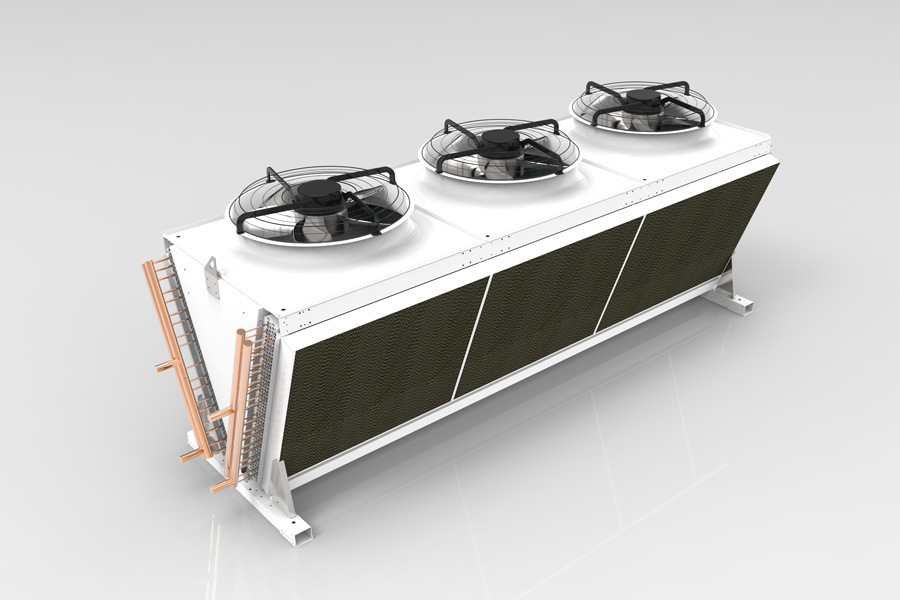

Compact BHC - SHC

Main features

Fin spacing: 4.8 mm – 6.3 mm – 7.7 mm

From 1 to 4 fans, Ø 275 – 350 mm

Low noise operation and reduced energy consumption

BENEFIT version available with LU-VE patented distributor JET-O-MATIC

Four different ranges for all installation requirements

| B2HC - BENEFIT Version | S2HC - Standard Version |

| 1400÷9400 W - 18 MODELS - 72 VERSIONS From 1 to 4 fans, Ø 275 mm | |

| B3HC - BENEFIT Version | S3HC - Standard Version |

| 3900÷27200 W - 27 MODELS - 108 VERSIONS From 1 to 4 fans, Ø 350 mm | |

TURBOCOIL®2 heat exchanger

The super-efficient Turbocoil® 2 heat exchanger has the highest possible ratio of capacity to cost. It is manufactured with:

- small diameter, high-efficiency copper tubes with inner helical grooving, specifically designed for the new refrigerants. A version for use with CO2 is also available and can be selected using the REFRIGER software.

- High-efficiency aluminium fins (TURBOFIN®2) with special turbulator profile to reduce dehumidification and frost formation.

Distributor and refrigerant circuit

The distributors and refrigerant circuits have been specifically designed to ensure the maximum efficiency of the unit cooler in all its different applications.

BENEFIT range (B): JET-O-MATIC distributor

SUPER range (S): Venturi distributor

Versioni speciali

ALUPAINT® fins in painted aluminium

CU copper fins

Ad hoc configurations: contact us